Frequently Asked Questions

What type of metals do you work with?

We work with virtually any metal alloy that can be melted, ferrous or nonferrous. Some common materials include iron, steel, stainless steel, manganese steel, cast aluminum, copper, brass, bronze, zinc, magnesium, titanium, nickel, cobalt, tin and more.

Is your company environmentally friendly?

Whenever possible, we reuse and recycle spent core, molding sand and other production byproducts. We also utilize a large portion of scrap metals that would otherwise go to a landfill.

What kind of turnaround time do you have?

While production time varies from project to project, we’re dedicated to meeting our client’s deadlines.

We will always do our best to accommodate rush jobs and emergency repairs into our production schedule.

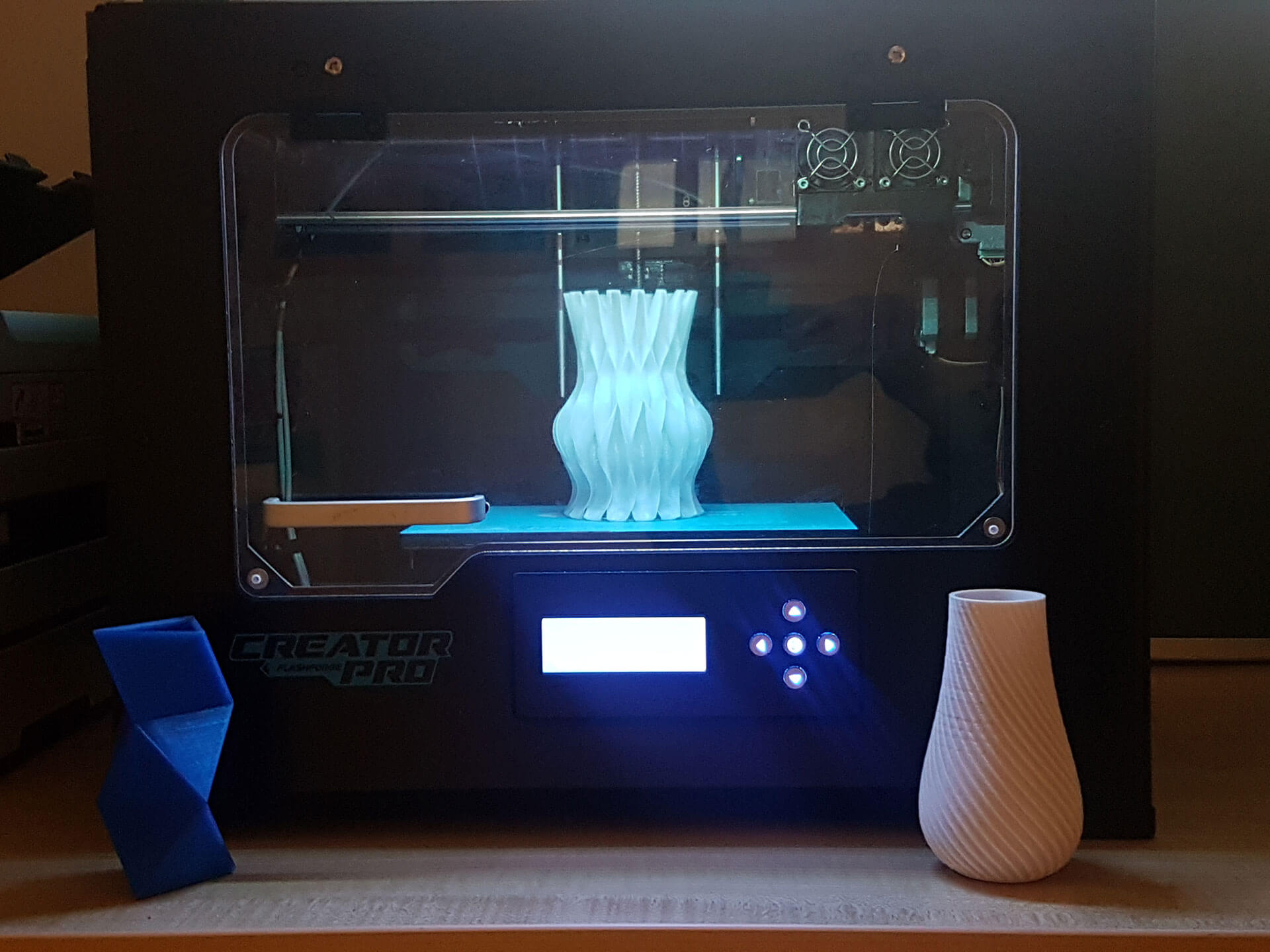

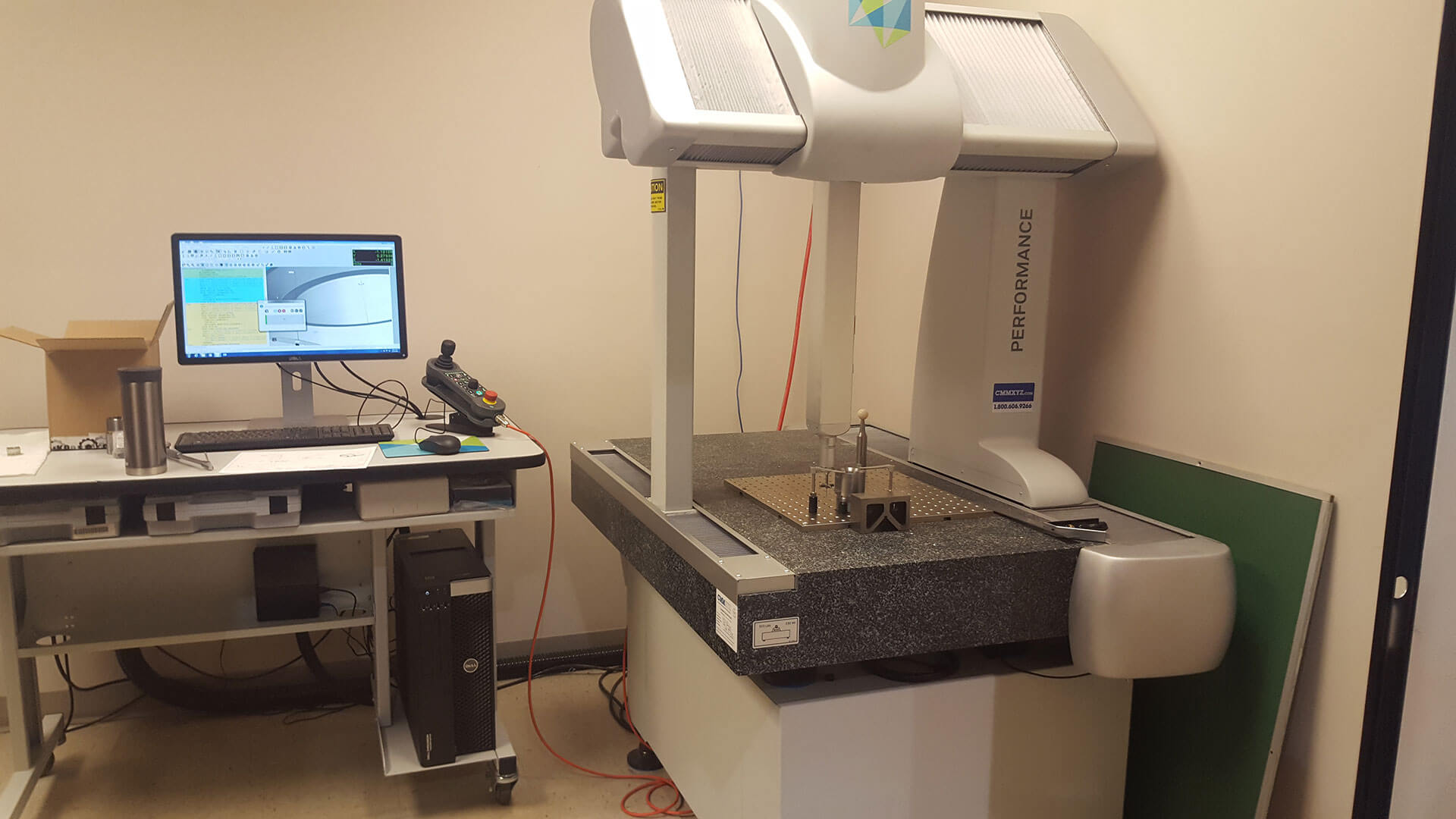

Can you repair or manufacture parts without drawings?

If you don’t have a technical drawing, we can arrange to provide you with a prototype based on a design consultation, however completed technical drawings are required for a finished product.

What type of drawing formats do you need?

We can work with all industry standard file types, including but not limited to .asm, .ckd, .dwg, .dxf, .igs, .ipt, .prt, .sab, .sat, .session, .sldprt, .srf, .stl, stp, .x_b, and .x_t files.

Do you provide emergency repair work?

Absolutely! We’re prepared to respond to on-site emergencies for immediate assessment and repairs.

What size of job can Quin-Ko handle?

Anything and everything - whether you’re looking for prototyping, small batch runs or large production orders, we’ll get the job done right and on time.

Do you deliver?

We will arrange shipping to anywhere within North America, provided this was requested prior to the job quote to allow for additional costs. Otherwise, all product must be picked up.

Call Local:

Call Local: